Gears are important for the wind power generation industry, just like most important machines worldwide. If these machines don’t have them or operable ones, they wouldn’t work. Gears also must have the precise specs to do the job right.

The Types and Design of Wind Turbine Gearboxes

The physical properties of wind turbines differ according to their types of gearboxes. Materials used to make these gearboxes include brass, aluminum, steel, and possibly other materials.

They have special features and distinctive forms. The following are the gearboxes that are normally used in wind turbines, along with their pros and cons:

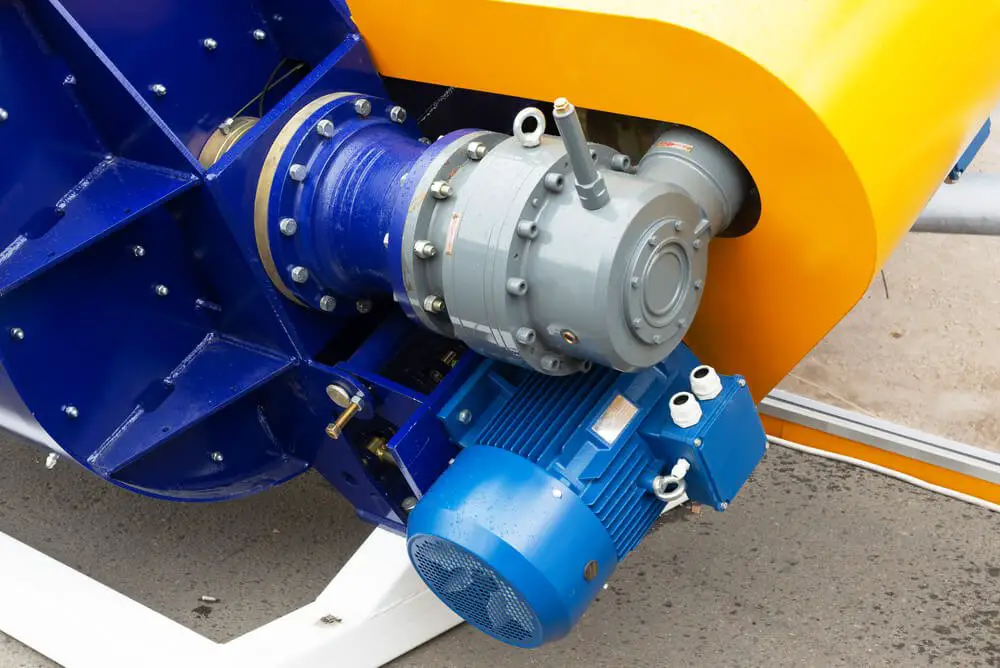

Planetary Gearbox

Planetary gearboxes are called planetary because they are similar to the solar system.

This gearbox’s components include an annular gear, a sun gear, and a planetary gear.

The gear in the center is the sun gear, and the gear on the outer ring with internal teeth is the annular cogwheel (annulus ring).

The planetary gears rotate around the grid with the assistance of the ring gear and sun gear, and these gears rotate around the sun gear. The planetary gearbox’s components are usually made of brass, stainless steel, or aluminum.

- Pros

They are highly efficient, and they have a high-weight torque and strong resistance to shock.

They are more stable than any other type of wind turbine gearbox.

Having a high-weight torque means that these gearboxes offer excellent power.

These gearing systems display higher power densities then gears on the parallel axis and thus can provide a huge transition within a small volume and several gearing options.

- Cons

When the steel gears come into contact with other gears, they can be noisy.

This design makes them susceptible to wear and tear, which causes the need for frequent and complicated maintenance. These planetary gears also require a complicated automatic wind turbine oil system.

Spur Gearbox

Spur gears are mounted on parallel shafts, and they possess straight teeth. These gears may have different gear ratios and sizes that meet the requirements for certain torque and speed. Spur gears usually contain brass or steel. Nylon and polycarbonate are other common construction materials of this gearbox.

- Pros

Spur gears offer efficient speed control, and they have a high torque output.

Wind turbines that require speed regulation strength and decreased speed, if needed, require these gears. People would have more control over speed and torque with spur gears.

- Cons

It is typically made of steel and can be noisy and wear out quickly, like a planetary gearbox. Thus, it is crucial to use the lubrication system regularly on spur gears.

Bevel Gearbox

The two types of bevel gearbox, spiral and straight teeth, may contain aluminum, cast iron, and other similar metals.

These gearboxes are not as common as the spur and planetary gearboxes. They are typically mounted in right-angle formations with a perpendicular shaft. This occurs due to either the spiral or straight teeth matching up between the two gears.

- Pros

Bevel gears are compatible with wind turbine systems with right-angle configurations. The most beneficial aspect of bevel gearboxes is their ability to be used where a right-angle gearbox is required.

- Cons

The cut of the poor teeth can cause noise and strong vibrations. So, if the teeth are not properly cut, noise and vibrations will be a common issue that eventually gets worse.

Helical Gearbox

Helical gears have a special-angled cut that allows smooth and gradual contact between all gear teeth. It is a quiet operation, and the materials are usually aluminum, cast iron, or iron. Wind power plants with huge and efficient performance use helical gearboxes.

- Pros

The wind turbine operation is fairly quiet with barely any noise. At the same time, they have high horsepower, and they are very efficient. Also, they don’t wear out fast.

- Cons

There may be a hard axle load, even though these gears don’t quickly wear out.

Worm Gearbox

Worm gearboxes are for units that require big loads and high speed. The worm gearbox can be made for right-angle systems. Worm gears are also resistant to wear and tear. They also produce low noise.

- Pros

The worm gearbox is easily accessible for maintenance. This configuration enables an easy gearing service with no problems encountered. Also, this gear creates a very low noise level, and it has a reliable operating system. Due to its design, the worm gearboxes are easy to maintain, so you can save money and time when it’s time for maintenance.

- Cons

This worm gear is poorly efficient. So, it is reasonable to only use it at low-capacity power plants, and only for a small amount of energy production.

These gearboxes are common among wind turbines. And like with any great product, there are pros and one or two cons. Thus, it’s best to get the right gearbox for the right wind turbine and just keep it maintained. Then, your wind turbine will continue to operate well.